We also design, manufacture and/or distribute other standard and custom made resistors and related products. Please contact us if you require resistor elements, discharge resistors, neutral grounding cabinets, resistive load banks, or custom resistor mounting.

Wirewound resistive elements consists of an open helical stainless steel wire wrapped around a tubular porcelain core, allowing for fast and efficient cooling. In general wirewound resistive elements are ideal for low current conditions, offering excellent power dissipation, stable resistance, and shock-proofing.

Edgewound resistive elements are strip type elements, essentially a stainless steel tape wound on tubular porcelain insulators. A rod is placed inside these resistive elements to form the resistive assembly. They are used in general for medium-level currents, touting shock-proofing, and compactness.

Generally used for low resistance and high current, grid resistors are made with punched steel sheet with holes at in each end for mounting. Grids are then stacked on insulated steel rods. Mica washers are inserted between grids for insulation, and the rods are mounted between steel end frames. To obtain the best electrical connection, we weld grids together.

Discharge Resistors are also referred to as Discharge Resistors or Bleed Down Resistors.

Discharge resistors are placed in parallel with high-voltage supplies to discharge an electric charge stored in a capacitor or battery. This is done whenever the equipment containing the capacitor or battery may need to be serviced or repaired.

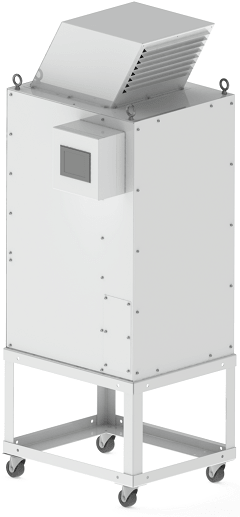

Neutral Grounding Cabinets are also referred to as Neutral Terminal Cabinets or Neutral Grounding Cubicles.

Neutral Grounding Cabinets are used to ground large generators and can include Current and Voltage Transformers, a Disconnect Switch, a Neutral Formation Bar, Surge Arrestors and Capacitors in addition to the Neutral Grounding Resistor.